Office of the Quartermaster General

Washington, D.C.

23 December 1952

29 October 1952

Note: Despite the widespread popular use of the term, no military service has developed a practical “bullet-proof” vest. Vests made of any presently-developed material strong enough to stop all high-velocity missiles would be too bulky or awkward for wear by soldiers in active combat. The armored vests developed by the U.S. military services are designed primarily to stop fragments of mortar shells, hand grenades and other types of low-velocity missiles—the type which cause the majority of battlefield wounds.

Development of body armor, including armored vests for Army ground troops was conducted during World War II by both the Army Ordnance Corps and the Army Quartermaster Corps.

Quartermaster efforts were directed toward development of non-metallic body armor and at the end of World War II had reached the combat test stage with an experimental vest armored with rigid plates of Doron, laminated plastic fibre-glass. The term Doron is derived from the name of Brigadier General Georges Doriot, World War II chief of the Research and Development Branch, Office of The Quartermaster General of the Army.

Body armor developed by the Ordnance Corps during this period included a 12-pound vest of aluminum plates and nylon fabric designated as M-12, which was adopted as a standard Army item by the end of World War II.

On 25 June 1947, the Army Quartermaster Corps was assigned primary responsibility within the War Department, for the development of helmets, body armor, and other armored clothing. At that time the only specific requirements for body armor was for over-all armor for engineer troops engaged in mine clearance work. A study was made by the Operations Research Office, Department of the Army, to determine the value of armor for the use by ground troops engaged in active combat. The report of this study, issued in 1949, was not favorable to the use of armor for active ground troops, partly because of the excessive weight of the standard models then available.

Immediately after it was assigned responsibility for body armor, the Quartermaster Corps began development on a new type of vest utilizing flexible laminated nylon duck, recommended by the Ordnance Corps as the best of all lightweight flexible ballistic materials. The fibres of nylon trap jagged fragments of low-velocity missiles, which cause the majority of combat wounds. (Multi-layered nylon was an important ballistic element in World War II U.S. Airman’s armor.) Ordnance Corps ballistic tests reveal that nylon, weight for weight, is superior even to steel in stopping fragments from exploding missiles.

The Army’s first laminated nylon body armor, developed in 1948 by the Quartermaster Corps, was a fully laminated two-piece vest (front armor and back armor) with a groin apron. It was similar to the World War II vest-and-apron armor of the Air Force.

Spot-laminating was substituted for full laminating to achieve greater flexibility in later models of the Army body armor and the groin apron was eliminated. In 1950 the Army nylon armor was redesigned as a one-piece vest. This model was the progenitor of the present Army armored vest.

Meantime the Department of the Navy also had been engaged in extensive body armor development, concentrating principally on the use of Doron. In 1950 experts of the Army Quartermaster Corps and the Marine Corps began joint experiments on various models utilizing both Doron and nylon. In 1951, 100 test models of a combination of Doron-nylon armor, for which the Quartermaster Corps furnished the fabric, Doron and webbing, and which were made by the Marine Corps, were shipped to Korea for test under supervision of a joint Army Marine Corps team. This vest used over-lapping, curved Doron plates around the upper torso and nylon duck over the shoulders. At the conclusion of the test in Korea, the Marine Corps continued development of the new-type Doron vest, which was subsequently standardized for issue to Marines.

After analysis of the results of the test, the Army Quartermaster Corps continued development of its all-nylon vest, since Ordnance Corps tests continued to affirm that the flexible nylon was superior ballistically to Doron. Modifications suggested by a representative of the office of the Army Surgeon General, a member of the joint Army-Marine Corps body armor mission, were incorporated in the Army nylon vest. From February to July, 1952, a total of 1400 of this new model of the Army vest (T 52-1) were shipped to Korea for tests by an Army body armor test team under direction of the office of The Quartermaster General. Minor modifications were made between shipments, based on recommendations of the test team.

In the summer of 1952, the Far East Command requested immediate supply of the latest Army type vest for issue to combat troops. Although field testing of this model had been completed, the vest had never been mass-produced. For this reason, vest of this type could not be furnished immediately and the Far East Command indicated that, although the Army armored vest was preferred, the Marine Corps’ Doron vest was acceptable to fill immediate requirements. Therefor, 31,017 of the Marine Corps vests were procured and shipped to the Far East Command. Five thousand Army-type vests also were ordered at this time for shipment to the Far East Command.

Delivery to the Far East Command of an additional 20,000 of the Army vests is scheduled for the period of January through May, 1953. Cost of these 20,000 of the Army vests, including price of materials furnished the contractor by the Quartermaster Corps, is $39.04 each.

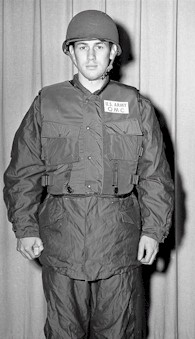

The Army armored vest currently being provided troops in Korea weighs approximately 8 pounds, and is made of 12 layer of flexible, spot-laminated Nylon-duck, enclosed in a heat-sealed water-repellent vinyl envelope. The T-52-2 Model (the 5,000 shipped to Korea late in 1952) is designed to be worn as an outside garment and has an outer cover of 6 ounce, nylon fabric. It has adjustable side straps to assure a snug fit. The T-52-3 Model (the 20,000 ordered for shipment to Korea early in 1953) is designed to be worn under the field jacket and is covered with light-weight 6 ounce nylon. New elastic side-laces insures a snug fit. Both models are fastened in the front with a zipper, plus a fly closure utilizing snaps. Both models are made in three sizes—small, medium, and large. The new Army vest (T-52-3) has an area of approximately six square feet; the earlier model (T-52-2), 5 ½ square feet.

Reports received by the Office of the Surgeon General of the Army on the combat testing of the new Army nylon vest show that the armor has been deflecting approximately 65 per cent of all types of missiles, 75 per cent of all fragments, and 25 per cent of all small-arms fire. The reports also state that the armor has reduced torso wounds by 60 to 70 per cent, while those inflicted in spite of the armor’s protection were reduced in severity by 25 to 35 per cent.

Although experience in Korea has established that both the current Army and Marine Corps types of armored vests are extremely effective in reducing combat casualties, the Army Quartermaster Corps is continuing body armor research, including tests of high tenacity yarns of different compositions, various cloth weaves, and various laminated structures. This work is being conducted in cooperation with industry and military agencies.