CPT Bruce E. Cox

Quartermaster Professional Bulletin – Spring 1994

On 8 Oct 93, during a four-day weekend, at approximately 0930 hours, the 16th Field Service Company was alerted to deploy to Somalia from Fort Lee, VA. The mission was to support a 1,800-soldier task force with laundry and shower services. This task force consisted of units from many different posts and included combat, combat support, and combat service support units. The 16th soldiers supported a United Nations compound October-December 1993 in Mogadishu during Operation Restore Hope.

Once the personnel recall was complete, the unit commander briefed key leaders on the deployment and passed out loading instructions. The 16th was given only 24 hours to load all equipment to perform their mission in an austere environment. Mission guidance directed the unit to deploy four of six organic M85-100 laundry units and four of seven, nine-head, portable shower units. The rest of the package was left to the unit’s discretion.

Unit Packing

Having previously deployed to Somalia, the philosophy for unit packing was “if the soldier does not have it on his back, he does not have it. ” Loading of support equipment began at approximately 1400 hours and continued until 2300 hours. Support equipment consisted of tents, cots, laundry detergent and, most importantly, the pin sets used to mark individual laundry items. This equipment filled four military-owned demountable containers (MILVANs) to capacity. Fortunately, the units in the 240th Quartermaster Battalion have MILVANs assigned to its property books. The support equipment for mission deployment is stored in MILVANs by platoon. This allows for rapid deployment and minimal searching for necessary items to perform the unit mission.

After preventive maintenance checks and services (PMCS) on all vehicles, they were staged and readied for commercial haul. Last-minute reparable exchange had to be performed on one laundry unit to bring it to operational standards, and this was done in a matter of hours. All vehicles and the MILVANs were completely ready by 0730 hours on 9 October. Commercial transportation was ready to pull the vehicles to the port of Savannah, GA, where the equipment would be shipped. The battalion transportation movements officer (TMO) followed the equipment to port to ensure loading and proper ship information for the 16th. This information was later used to track equipment and anticipate the arrival of equipment once the 16th was in Somalia.

Show Stopper

At the port, all rolling stock from the 16th was loaded onto a fast surface ship (FSS) that made the trip to Somalia in just 14 days. Despite the urging of the battalion TMO, it was decided to load the unit MILVANs on another ship. This ship was not scheduled to arrive until at least two weeks after the FSS. Because the MILVANs contained necessary equipment, this turned out to be a definite “show stopper.” The 16th would not be able to support the United Nations task force without the proper equipment such as laundry detergent, pin sets, and the portable shower units which were also stored in the MILVANs. Nevertheless, the 16th was deployed to Somalia on 26 October, well ahead of the MILVANs.

On 28 October, the 16th touched down in Somalia and were met by members of the 13th Corps Support Battalion (CSB) from Fort Benning, GA, the 16th’s new higher headquarters. As the battalion and the 364th Supply and Service Company helped with transition to operational status, the 16th began to plan for mission support. Since adequate support items to run the field laundry were unavailable in country, the decision was made that operations would begin when the unit could perform its mission to standard. As a benefit to the troops of Task Force 1-64, the commander of the 13th CSB suggested that the 16th use the commercial laundry facility during the night hours and process laundry for the Task Force. This support was welcomed by both the Task Force and the 16th. Soldiers were able to begin limited operations while awaiting equipment and site preparation. The 16th processed a total of 2,579 laundry bundles through the night shift initiative.

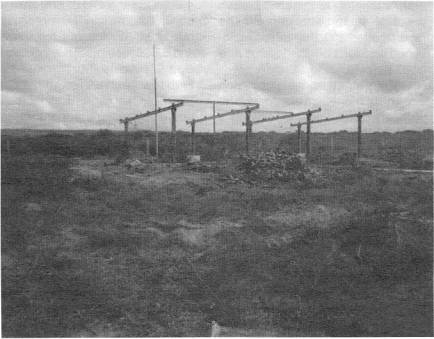

While waiting on the ship’s arrival, site preparation became critical. The base of operations for the task force was an unimproved site that had to be completely cleared of brush and cactus and graded to allow the laundry units to be pulled into position. This base became known as Victory Base, approximately three kilometers from Sword Base, home of Task Force 1-64. The site chosen for the laundry and bath site was more than adequate to provide proper drainage, a very important detail in a country that produces high malaria statistics because of swarms of mosquitoes.

When the ship arrived in mid- November, the 13th CSB transportation cell was on line to deliver the 16th MILVANs to their location. Unfortunately, the port began pushing MILVANs out as quickly as possible. Although the 16th MILVANs have very clear marking, two MILVANs were “lost” in the exodus from the port. The MILVANs were located through good luck and perseverance and, surprisingly, ended up at Victory Base. Even more of a surprise was that the two MILVANs needed for the operational start-up were the ones at Victory Base. With all in place, the 16th only needed eight hours to set up operations. The next morning, operations began with the first bundles of laundry turned in to the receiving point.

Army Standard

The Army standard for field laundry service is to wash one bundle of laundry per soldier every seven days. Each bundle consists of 20 pieces. One pair of socks counts as one piece. This standard bundle is limited by the number of laundry pins in one pin tray: 20. Each pin tray has safety pins with set numbers on them. For example “A-12” would be assigned to one bundle of laundry, and every piece of laundry in that soldier’s bundle would be pinned with a pin marked A-12. This allows the unit to separate bundles when they come from the dryer unit. This is important since there are as many as 10 bundles in a wash cycle at one time.

Also, as items go through the wash, pins come undone or break from the strain. This makes laundry identification next to impossible. This is the most prevalent way that field service units lose laundry. During the support phase at Victory Base, the 16th was not without its share of lost laundry. However, the bulk of laundry claims were for single pairs of socks or underwear.

The support of the 16th Field Service eventually went as far as processing individual laundry with a five-day turnaround for the force, two days better than the Army standard. This was seen as the only way to ensure that personnel had a clean change of clothes on a daily basis short of soldiers washing some of their own laundry.

Overall, the support provided for the buildup of troops was more than adequate, although belated. During the initial operations in Somalia, early in 1993, units in Mogadishu had to wash their own clothes for at least a month. In the future, unit equipment must be shipped to maintain unit integrity. If all equipment arrived on station and on time, the 16th would have been operational at least two weeks earlier and able to immediately begin operations. However, the operation was a total success and provided the soldiers of Task Force 1-64 an invaluable service and helped maintain the high morale of the soldiers.

At the time that this article was written in 1994, CPT Bruce E. Cox was Commander, 16th Field Service Company, Fort Lee, Virginia. His unit served in Mogadishu, Somalia, under the 13th Corps Support Battalion, one of the two Corps Support Battalions serving under the 507th Logistical Task Force supporting the United Nations Forces in Somalia.