CPT S. Carter Corsello

Quartermaster Professional Bulletin – Winter 1993

Operation Restore Hope served to illustrate a number of challenges that face logisticians in today’s armed forces. Logistics operations were fast-paced and extremely reactive, which resulted in a premium on quick, effective and flexible planning. I will offer insight for supply operation activities in the future by describing the organization and actions taken by soldiers of the logistics support activity (LSA) located at Jilib, Somalia, during February 1993.

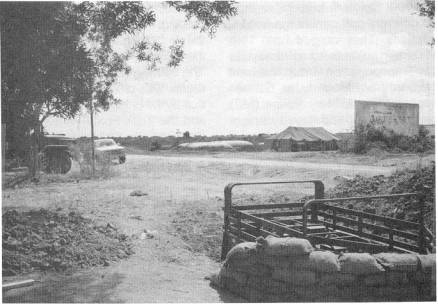

On 28 Jan 93, I was informed that I would go south and establish a logistics activity in the area of Jilib, a small village 120 miles from Mogadishu. The next morning I was commanding a 29-vehicle convoy to Jilib. After 17 hours of rough roads and mechanical breakdowns, we arrived in Jilib.

The mission of the LSA Task Force was to support approximately 1,350 soldiers from the Engineer Task Force and provide backup support for the 10th Mountain Division soldiers in the area. The 36th Engineer Group from Fort Benning, GA, was to build a road network into the heartland of Somalia. This would allow non-government organizations (NGOs ) the accessibility to feed and repatriate the interland. Their task force for the mission was named Durham. Their goal was to complete the road net- work by February 28.

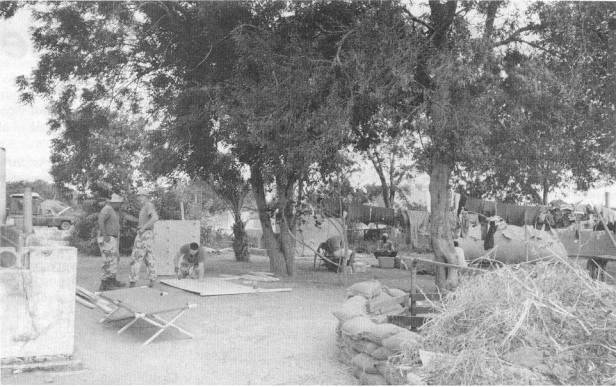

While the Engineers helped my assigned soldiers clear the site, I learned the capabilities of my activity and established the LSA’s chain of command. The LSA was composed of four basic functional areas: petroleum, oils and lubricants (POL), Class I (rations), water purification and maintenance support. There were 56 soldiers from 9 different companies, 2 battalions, and the group headquarters. Clausewitz’s statement “… in war, all things are simple, but even the simple things are difficult” could easily apply to many of the actions during the existence of the LSA.

The POL section consisted of 17 soldiers. The team worked extremely well together. During the first two days, all the soldiers were very busy getting the three 20,000-gallon collapsible tanks and equipment on the ground. It was impressive to see a team work so efficiently.

Our materials handling equipment was a high mobility materiel handler, more commonly called a “C.” It was one of the vehicles that broke on the convoy. Without lift capabilities, the team had to download the collapsible storage tanks and equipment by hand. Within eight hours of selecting the POL site, the collapsible tanks were in position, the initial supply of slightly less than 30,000 gallons were downloaded, and we served the first vehicle.

A POL subsection of two retail tankers and five soldiers had arrived a week earlier. They were to go forward with the 63d Combat Support Engineers (CSE) as they built the road toward Barbera. The requirement to have this asset on hand was unfounded. The 63d eventually moved 27 miles up the road that they built from the Task Force Durham’s base camp. The 63d built the remaining 30 miles to the link from there.

The 63d had a heavy expanded mobile tactical truck (HEMTT) tanker. It could travel the newly constructed road in 30 minutes. Our tankers took over an hour. In addition, their daily fuel consumption never came close to the original projections of 6,000 gallons a day. The Engineers’ fuel consumption estimate was based on all equipment running all day. They could only have so many pieces of equipment at one time actually building the road. The rest of the equipment could not maneuver. Their average fuel consumption was close to 1 200 gallons per day. We went to them and resupplied the HEMTT every other day.

The 60,000-gallon storage capacity of the field distribution system was not used. Full tankers came and were dispatched to Task Force Kismayo without even offloading. The average distribution from the storage site was just over 1,200 gallons a day for 8 to 12 vehicles.

Three soldiers from the 226th Quartermaster Company, Fort Drum, NY, were assigned to the Class I section under the 548th Supply and Service (S&S) Battalion. The building selected for the rations was one of the three buildings within our established perimeter. Since there were no entrances that materials handling equipment (MHE) could go through, all the supplies were placed in the building by hand.

Because the road was so rough, the initial couple of loads saw at least 30 percent water bottle loss. The bottom boxes would break, causing the rest of the load to shift. Two rooms of bottles stacked five feet high were the result. The loads were eventually stacked less than 5 cases high, and this resulted in less than 10 percent loss from breakage.

One mistake was sending B-rations into an area that could not prepare the food. The Class I warehouse was controlled by the 548th S&S Battalion. The operations officer of the 240th Quartermaster Battalion, the responsible headquarters, did not know the B-rations were coming. The 548th decided to send the rations, not the responsible headquarters. In the end, we issued a few B-rations. Just under 20,000 meals stayed at the LSA for the duration of the exercise until transported back on three trucks to Mogadishu.

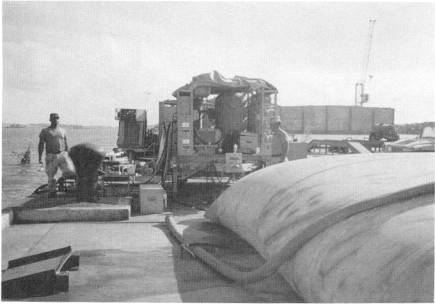

The water purification section arrived one week after the main body. The 14 soldiers comprising 2 teams arrived with 2 600-gallons per hour Reverse Osmosis Water Purification Units (ROWPUs), 8 3,000-gallon collapsible fabric tanks (onion skins), 2 20,000-gallon storage tanks, and other required equipment.

The collapsible 20,000-gallon tanks were to go next to the well where the ROWPU operated and be used for storage. This never happened. The well was not operable because the raw water pump’s vertical lift capability was only 20 feet. The well was 40 feet deep. The tasking to complete one of the wells in the Jilib area went to the Navy. Several wells were available, but the one tested and most ready for completion was the well at Bandar Salom. While we waited for the Navy engineers to arrive, one team replaced a 10th Mountain Division team on the bank of an irrigation canal located three miles outside Bandar Salom between Bandar Salom and the Task Force Durham base camp.

The canal location was not ideal. The intake was from surface water. Seemingly millions of “roily bugs” crawled over the equipment. The preventive medicine team reluctantly approved the water for bathing only. They later changed their mind when a soldier found a “roily bug” in his canteen. Attempts were made to prevent the bugs from getting into the tank. If the tops of the onion skins were off during the day, no bugs would get into the water. The bugs apparently sought the shadow of the cover. Unfortunately, by doing so, dust that carried cow fecal matter would land in the water because several herds passed the site daily.

The original site closed after the Navy arrived with the completion kit. The overall production of the Bandar Salom site was hampered by the ability of the sump pump to deliver water. It pumped at 16-gallons per minute (GPM) while the ROWPU could pull at 36-GPM. Thus, the well pump worked for two hours filling a 3,000-gallon bag, and the ROWPU worked for 20 minutes before it would have to shut down. The fix was to idle the production capabilities down to the same as the well pump. Also, no water was wasted. The “bad” water produced by the ROWPU recycled into the reserve tank along with the “not-so-bad” water. Together with the raw water from the sump pump, a production of 14-GPM was achieved.

The water purification section adjusted operation hours to meet the demand. Although no water needed to go to Kismayo, daily consumption in the Jilib area of operation was 4,000 to 6,000 gallons a day. The 331 soldiers at Bandar Salom used approximately 3,000 gallons per day by showering. The other units used less because of using Australian shower equipment.

The most helpful factor in the water mission was the ability to get water from Mogadishu. Each logistics package or “log pack” that arrived had 10,000 gallons of potable water carried by two 5,000-gallon tankers. The original concept of the tankers was to transport only enough water to start the retail operation of the 20,000-gallon storage tanks. I chose not to place the 20,000-gallon tanks until the ROWPU well site was operable. When the well was finally completed, Task Force Kismayo asked for one water team with storage capability to set up at the port for wash rack operations. That is where the two 20,000-gallIon collapsible tanks went.

I continued to draw water from Mogadishu even though the Bandar Salom well production could have kept up with the area demand. One problem was that each unit lacked enough organic potable water storage capability for the demand without traveling the 15 to 40 miles with the water trailers or “water buffaloes” several times a day. Also, the task force elements, the LSA included, had no storage capability. The fix: place 3,000-gallon onion skins at each site. In doing so, the 5,000-gallon water tankers had to stay to distribute as needed. The soldiers and equipment were replaced each log pack. The 10,000 gallons delivered each log pack satisfied the Task Force Durham base camp and 63d CSE, who had moved forward, while the ROWPU produced mainly for the Bandar Salom camp only.

The original orders for the maintenance support team (MST) told them to “provide direct support maintenance.” The company’s orders given to the staff sergeant in charge of the MST said to report to the S 1 of the task force. My operations order stated that the staff sergeant was to report to me. Not until we had good communications was the issue settled. The MST was part of the LSA, not Task Force Durham.

The noncommissioned officer in charge (NCOIC) of the MST relayed that he was doing organizational maintenance for the Engineers and LSA. The Engineers, as well as us, formed without organizational capabilities. This provided good opportunities to cross-train some of the younger soldiers in different levels of maintenance.

Two specialists operated the radio teletypewriter (RATT) effectively to get accurate communications back and forth from battalion. The Logistic Status Report (LOGSTAT) was sent through teletype. The other great aspect of the RATT was the Military Affiliated Radio System (MARS) capability. This is where amateur radio operators in the U.S. receive a transmission and complete a phone patch. The original antenna configuration did not allow for MARS capability. The fix was to make a field expedient antenna out of WD-1 wire.

Within the 17 nights the team had MARS capability, the team made over 500 attempts at communication, with more than 350 connections. The connections started around 2200, and many times continued until the operators had to switch back to normal operations at 0600. Soldiers from more than 30 different companies made connections. They ranged from 10th Mountain soldiers from Kismayo to 7th Transportation Group line-haul soldiers from Mogadishu. On two occasions, a Military Police (MP) platoon stopped and stayed the night just to get the opportunity to make calls back home.

The Joint Task Force commander’s visit happened to coincide with a ceremonial raising of the Somali flag in Jilib in front of the designated civic building. This was the first time since the conflict began that the Somalis had the national flag displayed in town. The building had nothing more than rooms with crude tables and chairs built by the Engineers. Children sang, and the Task Force Kismayo commander gave a plaque to the head elder. Shortly after the visit, the Engineers neared completion of their mission. The 63d CSE linked up with the 642d CSE by the13th and had a Restore Hope Road opening ceremony on February 18.

Though the Engineers completed their mission over two weeks early, they continued operations from the base camp in Jilib. On February 19, they picked March 1 as the date to move to the base camp in Merca. We began to pull stakes on February 21. Realizing that the need for a full petroleum distribution system was unfounded, the POL team uploaded the fuel into four tankers.

C/3-14 Infantry moved out on February 22. This was to coincide with the Belgians coming to their location. The scheduled change of command from U.S. to Belgian control was the following day. However, the Infantry moved out as scheduled, but the Belgians stayed in Kismayo. Apparently the two primary Somali clan leaders in the area began fighting again. This left the base camp in Jilib defended by fewer than 40 soldiers of the two task force elements, the LSA and the Task Force Durham headquarters.

Actions at the base camp included moving the remaining rations within Task Force Durham’s portion of the camp, a plan to consolidate forces inside the base camp of both task forces, and increased guard activity. The LSA’s primary mission became self defense, not supply, though supply activities still occurred. On March 1, most LSA elements returned to their parent units.

The single most important lesson I learned as the commander was the importance of a concise, coordinated command which ensures that the various command elements respect the activity as a separate element regardless of unit ties to other commands. All coordination of effort must flow through the responsible headquarters. A taskforce commander will rarely have authority for missions such as the LSA in Jilib. Further, the commander may not ever gain direct rating power over the NCOs. Does the NCO follow his rater or the officer on site? Both have jurisdiction. One has authority. Luckily, no conflict of command jurisdiction affected the mission. It occasionally did, however, hamper operations.

Overall, direct resupply would have been a better way to use assets than the LSA (logistics base) concept. Individual logistics packages directly from the direct support units in Mogadishu could have served this area amply with the same number of soldier requirements for the logistics train, yet without the overhead of the LSA itself. Based on the projections given, the logistics base concept seemed sound. In reality, there were only three customers. We supplied them with more service than doctrine requires. We were successful completing the mission. A Quartermaster rarely has the opportunity to service fellow soldiers as we did in Somalia.

The following units comprised the logistics support activity (LSA):

- Headquarters and Headquarters Company (HHC) 593d Area Support Group

- HHC, 240th Pipeline and Terminal Operating Battalion

- 267th Pipeline and Terminal Operating Company

- 418th Transportation Company

- 360th Transportation Company

- HHC, 548th Corps Support Battalion

- 18th Quartermaster Platoon (Perishable Subsistence)

- 226th Supply Company (Direct Support)

- 602d Maintenance Company

CPT S. Carter Corsello has a bachelor of Arts degree in psychology from Knox College, Galesburg, Illinois. He is also a graduate of the Quartermaster Officer Basic Course, Airborne and Rigger schools. His previous assignments include Platoon Leader, 543d Heavy Materiel Supply Company, Platoon Leader and Accountable Officer, 295th General Supply Company, Fort Lewis, Washington; and Group Budget Officer, 593d Area Support Group, Somalia. At the time this article was written in 1993, he was attending the Quartermaster Officer Advanced Course. His next assignment was Taegu, Korea, 4th Rigger Detachment Commander.